Description:

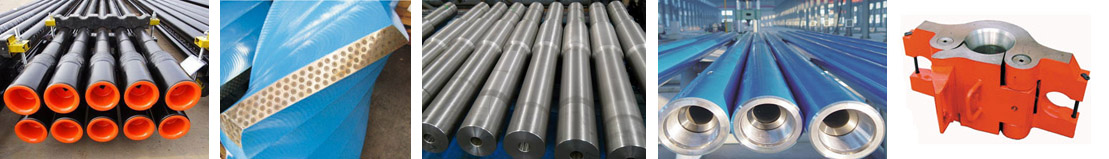

BOBAN main products including drilling mud pumps, liners, pistons, valves & valve seats, piston rods, extension rods, modules, pulsation dampener, liner & valve cover, cross-head, flange, etc. All of our products are strictly produced according to international standard-7K and ISO9001 Standard. Boban series mud pump spares available for both domestic and international brands like BOMCO, EMSCO, NATIONAL, OILWELL, IDECO.

Technical Parameter:

BOMCO

F-500

F-800

F-1000

F-1300

F-1600

F-1600L

F-2200L

LANSHI

F-500

F-500

F-500

F-1300

F-1600/F-1600L

F-1600H

3NB500C

3NB1000C

3NB1300C

3NB1600

P-800

P-1000

P-1300

P-1600

P-2200

HONGHUA

HHF-500

HHF-800

HHF-1000

HHF-1300

HHF-1600

HHF-1600HL

HHF-2200HL

RONGSHENG (RS)

RSF-500

RSF-800

RSF-1000

RSF-1300

RSF-1300L

RSF-1600

RSF-1600HL

RG

RGF-500

RGF-800

RGF-1000

RGF-1300

RGF-1600

QINGZHOU (QZ)

QZF-500

QZF-800

QZF-1000

QZF-1300

QZF-1600

QZ3NB-800

QZ3NB-1000

QZ3NB-1300

QZ3NB-1300A

QZ3NB-1600

RONGLI (RL)

RL-F500

RL-F800

RL-F1000

RL-F1300

RL-F1600

RL-F2200

RL-3NB350

RL-3NB500(A)

RL-3NB600

RL-3NB800

RL-3NB1000 (A/D)

RL-3NB1300 (A/D)

RL-3NB1600

TSC

WF-400

WF-450

WF-700

WF-1000

WF-1600

EMSCO

F-350/500

F-650

F-800

F-1000

F-1300

F-1600

FA 1300

FB-1300

FA-1600

FB-1600

DB-550

D-300

D-700

NATIONAL

8-P-80

9-P-100

10-P-130

12-P-160

14-P-220

OILWELL

A-600-PT

A-850-PT

A-1100-PT

A-1400-PT

A-1700-PT

A-350

A-560

A-650

A-850

A-1100

A-1400

A-1700

IDECO

T-500

T-800

T-1000

T-1300

T-1600

WIRTH

TPK-1000

TPK-1300

TPK-1600

TPK-2000

TPK-2200

ELLS WILLIAMS

E-447

E-2200

W440

W446

GARDNER DENVER

PZ-7

PZ-8

PZ-9

PZ-10

PZ-11

PZ-L

PA-8

FY-FXD

FO-FXO

FD-FXX

FG-GXG

RUSSIA PUMPS

UNBT 650

UNBT 950

UNBT 1180L

UNB 600

NBT 600

ETC.

Features & Benefits:

Bi-metal Liner

Features

Boban bimetal liner, international standard complaint, provides wear-resistant outer sleeve and high chrome corrosion-resistant inner sleeve. The material of liner is ZG45 steel, the high chrome liner has high rigidity of HRC≥61-65 after heat treatment.

Advantages

Production Process: The

bi-metal cylinder Liner of our company combined with the advantages of abrasion

hot-forging out liner and anticorrosion high chrome inner liner. The out liner

is made of high quality carbon steel by hot pressing forming. Its tensile

strength is over 900000psi. The inner liner is made of high-chromium alloy by

centrifugal casting. The

bimetal liner offers long service life of about 1000 hours, which is 2 to 3

times the lifetime of common ones in severe environment.

Ceramic Liner

Features

Compared

with the metal liner, the ceramic liner is wear and corrosion resistant and has

extended working life. The ceramic liner helps reduce drilling cost and labor

intensity. Made of internationally advanced, new material toughened zirconium

oxide, the liner provides fracture toughness of K10-15Mpa (10 times that of the

traditional one), and bending strength of σ600-800Mpa. The ceramic liner has

excellent wear and corrosion resisting properties, with the Weber number being

m18 and the elastic modulus of E200Gpa.

Advantages

1. The ceramic liner is the best choice for high pressure mud pumps. It is

manufactured strictly in accordance with specific technical standards by use of

advanced processing techniques. The ceramic liner comes in various

specifications, which come in Φ150~180×310~440mm.

2. Ceramic liner widely used in tough environments such as deep oil reservoirs,

hard stratum, and offshore oil and natural gas exploitation.

3. The service life is 5 times higher than bi-metal liner, up to 4000 hours.

5. It can improve

drilling efficiency and reduce the cost of maintenance and labor.

4. Zirconia ceramic

liner has various advantages, such as wear-resistance, erosion-resistance, high

pressure-resistance, high hardness, and so on.

Mud Pump Valve Assembly

Features

Mud

pump valve assembly is the key component of the hydraulic end of the mud

pump. The valve assembly consists of valve body, valve rubber, valve nut, guide

frame, gland, clamp spring, steel ball, etc. (i.e. valve assembly with valve

seat removed).

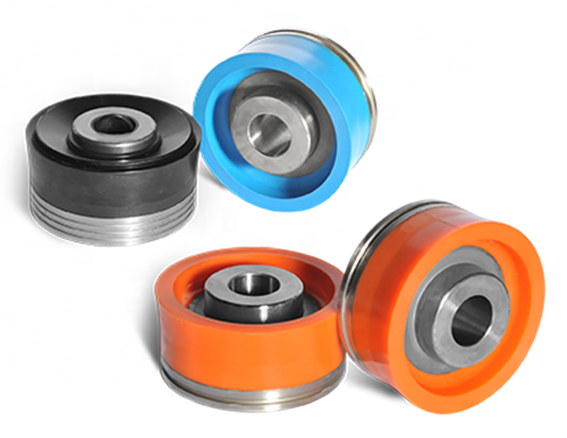

Mud Pump Piston

Features

Extra strong sealing area increases run times even at pressures up to

7500 psi.

Reduced maintenance Reduced operational costs.

Specially engineered Urethane compound, provides: high resistance to

water, oil and synthetic based drilling fluids.

Temperature Resistance up to 300(150˚C)

Superior resistance to tear, abrasion and extrusion.

Available in size 4", 4.5", 5". 5.5". 6".

6.25", 6.5", 6.75", 7".

Well-designed piston body for strong bonding with urethane and reduced

weight.

Mobile:+86 18710316881

Tel:+86 029 89240853

Email:sales@boban-oiltools.com

Add:No. 1511, Block C, Haibo Guangchang, Fengcheng 9th. Road, Weiyang District, Xi'an, China

We chat