In oil drilling and workover operations,

downhole fishing is an essential step in retrieving fallen objects (known as “fish”)

,such as broken drill pipes, tubing, and tool fragments. These fish can

severely disrupt operations and cause huge economic losses. Fishing tools are

scientifically classified by their fishing methods, with six typical types

widely applied in the industry: taper tap, die collar, overshot, fishing spear,

junk basket, and fishing cup. Each tool has its unique structural features and

working principle, suitable for specific downhole operation scenarios.

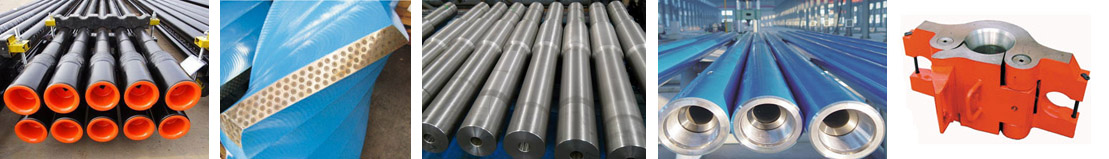

1. Taper Tap: Internal Thread-Forming

Fishing Tool

The taper tap is an internal fishing tool

designed to retrieve perforated fish by forming threads inside their inner

holes. It features an integral long conical structure, consisting of a joint

and fishing threads. The thread surface is hardened to HRC 60-65 for high

strength and wear resistance, with common thread specifications of 55° thread

angle and 8 threads per inch, which facilitates thread forming with lower

torque. Its working principle involves lowering the tool into the fish's inner

hole, applying appropriate drilling pressure, and rotating the drill string to

force the fishing threads to squeeze into the inner wall and form threads. When

the formed threads can bear sufficient tension and torque (usually 3 or more

threads), the fish can be lifted or unscrewed and retrieved. It is mainly used

for fishing casing, tubing, and drill pipes with inner diameters ranging from

30mm to 75mm in 140mm casings, especially effective for pipe-type fish with

couplings.

2. Die Collar: External Thread-Forming

Fishing Tool

As an external fishing counterpart to the

taper tap, the die collar retrieves fish by forming threads on their outer

walls. It has an integral long cylindrical structure composed of a joint and a

body, with the same thread specifications and material strength requirements as

the taper tap. Its working principle is similar to that of the taper tap: the

tool is lowered to enclose the fish's outer surface, then drilling pressure is

applied and the drill string is rotated to make the internal fishing threads

bite into the outer wall and form a secure connection. The die collar is

suitable for fishing pipes and rods with outer diameters between 67mm and 92mm

in 140mm casings, especially for cylindrical fish without internal holes or

with blocked inner holes. Its advantage lies in the large annular

thread-forming area, which is less likely to damage the fish top or casing,

though it has a smaller gap with the casing and poses a risk of sticking.

3. Overshot: External Clamping Fishing Tool

The overshot is a widely used external

fishing tool primarily for retrieving smooth tubular fish. Its core structure

includes an upper joint, a barrel, slips with serrated threads, and a guide

shoe. The slips generate radial expansion force when the tool is lifted,

ensuring a tight grip on the fish. During operation, the guide shoe helps align

the overshot with the fish top, allowing the tool to enclose the fish. As the

drill string is lifted, the conical fit between the mandrel and slips forces

the slips to bite tightly into the fish's outer wall. A notable feature of most

overshots is their retrievability: if the fish is stuck and cannot be lifted,

applying a downward impact and rotating the drill string 2-3 turns can

disengage the slips from the fish, enabling safe tool retrieval. Additionally,

the overshot is equipped with a sealing ring, allowing well flushing

circulation after entering the fish, and can even straighten slightly deformed

fish tops.

4. Fishing Spear: Internal Clamping Fishing

Tool

The fishing spear is an internal fishing

tool that grasps fish from their inner cavities, with common types including

sliding block spears and retrievable spears. Its structure typically consists

of a mandrel, slips, a release ring, and a guide shoe. In the free state, the

outer diameter of the slips is slightly larger than the inner diameter of the

fish. When the spear enters the fish cavity, the slips are compressed to fit

the inner wall, generating outward expansion force. Lifting the mandrel

increases the radial force of the slips, making them bite firmly into the inner

wall to achieve fishing. The retrievable design ensures operational

flexibility: if the fish is stuck, applying a downward impact to the mandrel

can disengage the slips from the mandrel's serrated threads, and rotating the

drill string allows the slips to retract, enabling tool withdrawal. It is

widely used for fishing tubing and drill pipes, and can also be used with

jarring tools for jarring and stuck release.

5. Junk Basket: Debris Collection Fishing

Tool

The junk basket is specialized in

collecting small downhole debris, such as drill bit teeth, bearing fragments,

and rock cuttings. It usually adopts a reverse circulation structure, composed

of an upper joint, a barrel, a basket frame, and a milling shoe. After lowering

the tool to the well bottom, a steel ball is dropped to block the central

channel, forcing drilling fluid to circulate reversely through the barrel's

annular space. The reverse circulation generates a vortex at the bottom,

carrying debris into the basket frame. Some models are equipped with a magnetic

core to adsorb ferrous debris, further improving fishing efficiency. During operation,

the tool is rotated and lowered slowly to ensure full collection of debris,

playing a crucial role in cleaning the wellbore and preventing secondary

downhole accidents caused by debris.

6. Fishing Cup: Debris Settling Fishing

Tool

The fishing cup is another tool for

retrieving small debris, often used in conjunction with drilling or milling

tools. Its design features a large-diameter barrel with a small-diameter

mandrel at the cup mouth, creating a sudden change in drilling fluid flow

velocity. When drilling fluid passes through the cup mouth, its flow velocity

decreases significantly, reducing its carrying capacity and causing heavy

debris to settle into the cup. Unlike the junk basket, the fishing cup requires

no special operation and works synchronously with normal drilling or workover

processes. It is particularly effective in catching heavy drilling cuttings and

metal debris that cannot be carried out by normal mud circulation, helping to

keep the well bottom clean, extend drill bit life, and reduce accidental bit

damage.

These six fishing tools, classified by

their distinct fishing methods, form a comprehensive downhole fishing system.

Their rational selection based on fish type, size, and downhole conditions is

crucial for improving fishing efficiency, ensuring operational safety, and

minimizing project delays and economic losses in oilfield operations.

Mobile:+86 18710316881

Tel:+86 029 89240853

Email:sales@boban-oiltools.com

Add:No. 1511, Block C, Haibo Guangchang, Fengcheng 9th. Road, Weiyang District, Xi'an, China

We chat