In oil and gas industry, drilling bits are the critical tools that enable exploration and production---their performance directly impacts drilling efficiency, cost and project timeline. Choosing the right drilling bit for downhole condition is a necessary prerequisite for optimizing operations.

Common Drilling Bits Types in Oilfield Operations

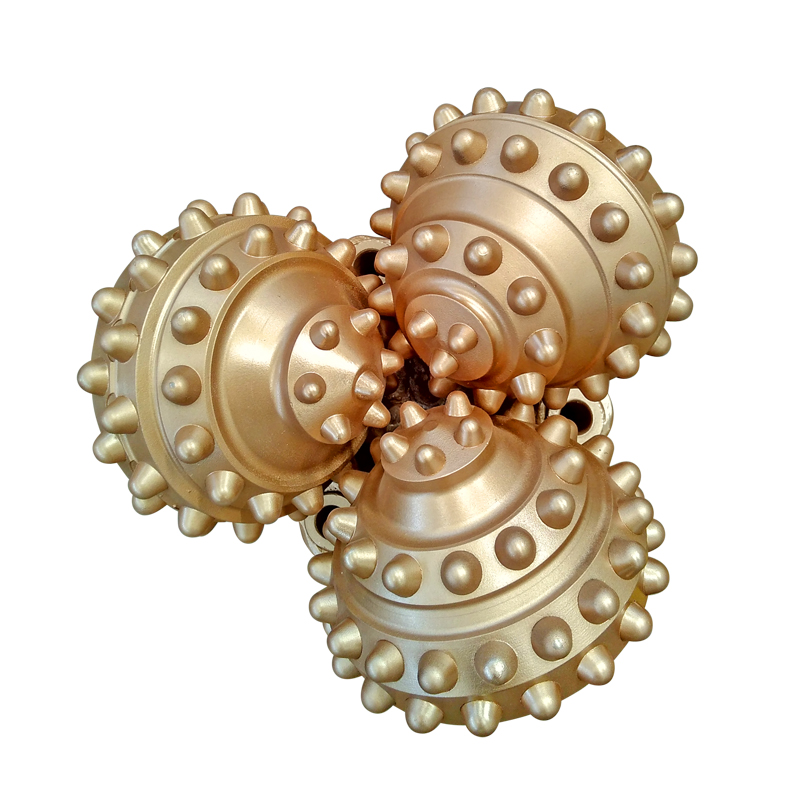

1. Tricone Drill Bits

The most traditional and widely used option, tricone bits are equipped three rotating cones with teeth (either milled or insert). Cones roll and Crush rock as you drill. It is suitable for soft to medium-hard formations (e.g., sandstone, limestone) and are valued for their durability in high-torque environments. However, it performance maybe limited in extremely hard rock formations.

2. Diamond Drill Bits

Engineered for hard, abrasive formations (e.g., granite, quartz), diamond bits use synthetic diamond cutters to grind through rock. In complex downhole conditions,they offer longer service life and faster drilling rates than tricone drilling bit, making them ideal for deep well drilling--thought their higher upfront cost requires careful cost benefit analysis.

3. Auger Drill Bits

Suitable for unconsolidated formations(e.g., clay, loose sand), auger bits use a spiral flute to remove cuttings efficiency. They are commonly used in shallow exploration or for soil sampling, as their design prevents clogging in soft, high-sediment environments.

4. Specialized Bits (e.g., PDC Bits)

Polycrystalline Diamond Compact (PDC) bits combine diamond cutting teeth with a tough cemented carbide substrate through a high-temperature, high-pressure sintering process and are fixed to the drill bit body by inlay welding. They deliver exceptional speed in soft-to-medium and are a popular choice for horizontal drilling ( a type of operation with extremely high requirements for precision and efficiency).

How to Select the Right Oilfield Drill Bits

1. Analyze Formation Properties

Start by assessing the rock’s hardness, abrasiveness, and porosity.

For example:

Soft, sticky formations: Tricone bits with milled teeth

Hard, abrasive formations: Diamond or PDC bits

2. Evaluate Drilling Parameters

Consider factors like well depth, rotation speed (RPM), and weight on bit (WOB).

High-RPM operations pair best with PDC bits, while tricone bits handle higher WOB in deep walls.

3. Cost vs. Performance Tradeoffs

While diamond bits have a higher initial cost, their longer service life often reduces overall drilling cost in hard formations. For shallow, low-abrasion wells, tricone bits may be more cost-effective.

A

frequent question in field operations is: How to calculate drilling bit

economics? This involves comparing total costs (bit purchase + operational

downtime) against drilling rate and service life.

For example, a $5000 diamond drill bit that drill 1000 feet in 10 hours may be more cost-effective than a $2000 tricone bit that drill 500 feet in 8 hours.

In summary, drill bit selection is a data-drive decision that balances formation conditions, operational goals and cost. By understanding the strengths of each bit type, oil and gas operator can minimize downtime, reduce expenses, and improve well productivity.

Mobile:+86 18710316881

Tel:+86 029 89240853

Email:sales@boban-oiltools.com

Add:No. 1511, Block C, Haibo Guangchang, Fengcheng 9th. Road, Weiyang District, Xi'an, China

We chat